Here’s how Heat Recovery Wheels work.

Heat recovery wheels are typically installed in an HVAC system’s supply and exhaust air ducts. The supply air duct carries fresh air into the building, while the exhaust duct carries stale air.

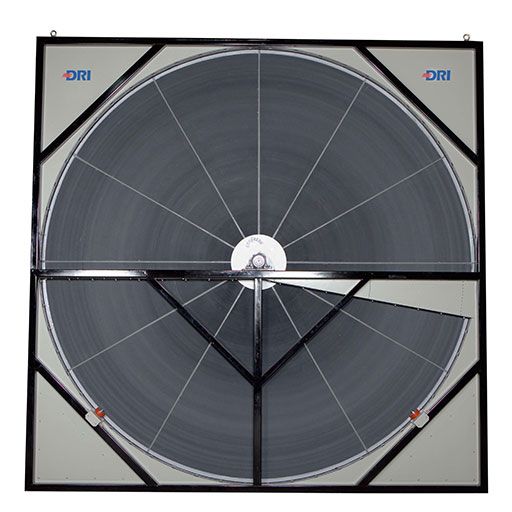

As the two air streams flow past each other, the heat recovery wheel rotates to transfer heat energy from the warm, stale air to the cool, fresh air. This transfer of heat energy occurs using a heat-absorbing material typically made of aluminum or a similar metal for sensible wheels and a moisture-absorbing material like silica gel or a zeolite molecular sieve for an Enthalpy recovery Wheel.

The heat recovery wheel captures the heat energy from the outgoing air stream as it passes through the heat-absorbing material. The wheel then rotates and transfers this heat energy to the incoming air stream as it passes through the same material in the opposite direction.

As a result, the fresh air entering the building is pre-heated, while the exhaust air leaving the building is cooled. It helps reduce the HVAC system‘s overall energy consumption, as less energy is required to heat or cool the incoming air.

Benefits of Heat Recovery Wheels

Heat recovery wheels are most effective in climates with a significant temperature difference between indoor and outdoor air. In colder climates, the wheels can help to reduce heating costs by pre-heating the fresh air, while in warmer climates, they can help to reduce cooling costs by pre-cooling the fresh air.

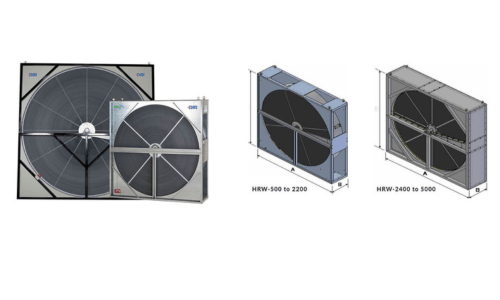

Energy recovery wheels can be separate equipment or come pre-installed in an air handler.

Caution: It is important to note that proper maintenance and cleaning of the heat recovery wheel is essential for optimal performance and energy savings. Dirty or clogged wheels can reduce the system’s effectiveness and increase energy consumption.

Types of Heat Recovery Wheels

One type will capture sensible heat only; the other is an enthalpy wheel, often called a desiccant wheel, which will catch sensible and latent heat.

Sensible Heat Wheel

With the use of a sensible heat recovery wheel, the dry bulb temperature of the air will be regulated depending on the outdoor temperature and setpoint. There will be no effect on the air’s moisture content or latent heat, as no moisture is transferred between the two air streams.

Enthalpy Wheel

Using an enthalpy wheel or total energy wheel will affect the moisture content or latent heat of the air. Both sensible and latent heat will be transferred using an enthalpy wheel. The amount of moisture transferred depends on the water vapor in the air. Moisture is shared between the two airstreams using a desiccant that absorbs or adsorbs water vapor from the high-pressure vapor airstream and releases it into the lower-pressure vapor airstream.

Capacity Control of Heat Recovery Wheels

When the system’s load varies, the wheel can adjust its speed using a variable frequency drive (VFD), or a bypass duct can be installed around the wheel to reduce the volume of air that travels through the heat recovery wheel.

The Heating Season for Heat Recovery

When heating is required and the temperatures outside are freezing, a heat or energy recovery wheel can save energy by removing heat from the exhaust airstream. No matter the season, an energy recovery wheel can retrieve needed warmth or expel unwanted heat from the airstreams.

How Can We Help You?

At DRI Rotors, we’re dedicated to providing optimal solutions for maintaining the efficiency and longevity of heat recovery wheels, an integral component of modern HVAC systems. We understand that the proper upkeep of these units is critical in ensuring not just the consistent performance of the systems but also the quality of the indoor air and the overall energy efficiency of the building.

Our range of services extends beyond providing high-quality, durable heat recovery wheels. We also assist our customers in maintaining their equipment to ensure peak operation. This involves regular inspection of the wheels, assessment of their condition, and recommendations for repair or replacement when necessary. Additionally, our expert technicians provide invaluable advice on preventative maintenance measures to minimize wear and tear and prevent potential breakdowns.

We also understand the evolving industry needs and the importance of energy-efficient solutions. Hence, we continuously invest in research and development to innovate and upgrade our heat recovery wheels. It ensures our products meet and exceed industry standards while contributing to energy conservation and sustainable business practices.