DRI has always been in the forefront of Air Treatment technologies. Our group is the fastest growing Adsorption Technology group in the world today.

We have several patents for our key technologies filed and accepted globally. (more details are available on request)

A dedicated team of scientists, research chemists and engineers are working on breakthrough work with the end objective of market introduction of truly innovation tech. The company has several patents filed and granted globally for the technologies, products and processes developed.

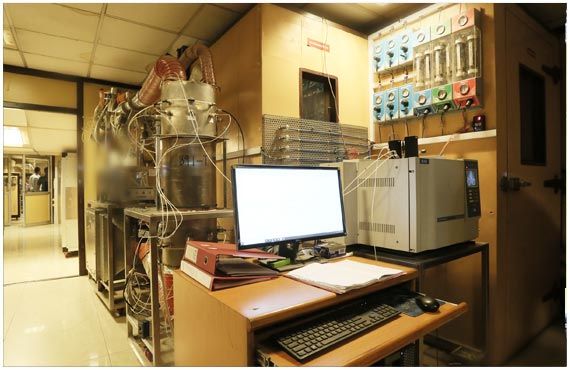

DRI has continuously invested in product and technology specific testing labs. DRI'sR&D facilities are recognized by the Department of Science and Technology and are the best in the environmental control industry, worldwide, in the corporate sector.

Our state-of-the-art R & D Labs are very versatile and regularly used for the following (as example):

At DRI, we use a unique and a first of its kind Testing Facility for the performance evaluation of Energy Wheels in association with Intertek Testing Services, Cortland (Intertek Associates with AHRI for the AHRI 1060 Program). It is designed for performance evaluation of Energy Wheels:

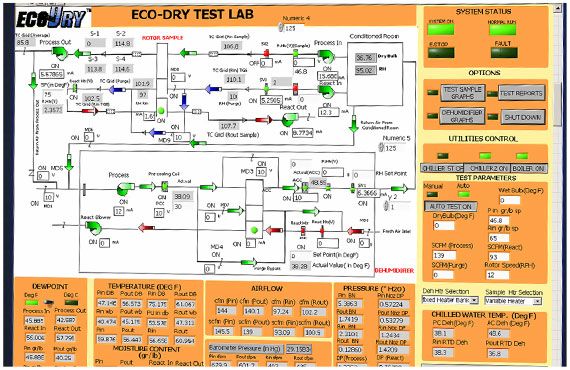

One of the most advanced labs in the world for desiccant rotors. More details can be provided on request. EcoDry Lab tests rotors capable of delivering desired dew points for applications in Pharmaceuticals, Food, Commercial Fresh Air Systems etc. and extremely low dew points for specialized applications like lithium Battery Rooms & Plastic Dryers.

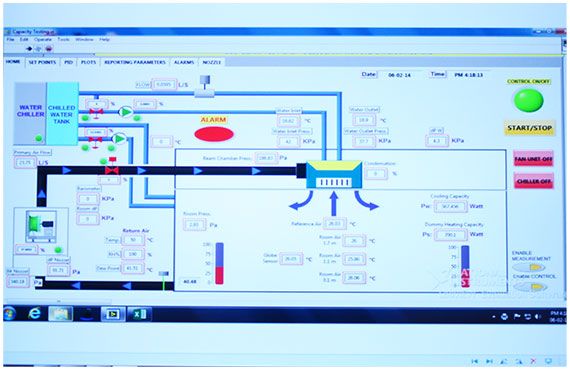

We have developed a unique and a first of its kind Testing Facility for the performance evaluation of Active Chilled Beams in association with WSP Laboratory Germany. The laboratory is designed to meet the testing criteria of various standards. In addition to the capacity testing, the laboratory is designed to have flexibility and adaptability for application testing using multiple beams at a given time.

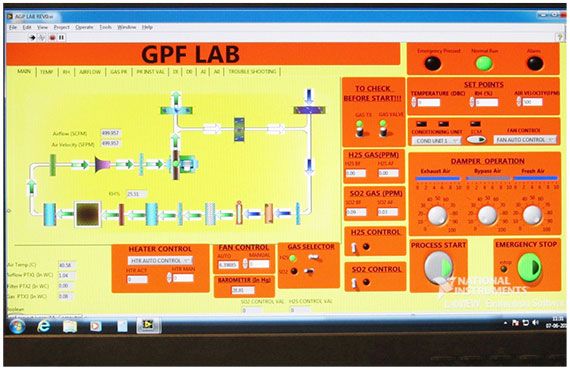

For testing performance of Granular and Honeycomb Media. More details can be provided on request.

We have developed a special Testing Facility for the performance evaluation of evaporative cooling pads. The laboratory is designed to meet the testing and measuring criteria for Temperature, airflow. pressure and moist air properties as per ASHRAE Standards 41.1, 41.2, 41.3 and 41.6 respectively.

One of the most advanced labs in the world for VOC capture and abatement. More details can be provided on request.

The DRI honeycomb / fluted media draw inspiration from the nature's own work of art - the honeycomb. The honeycomb structure combines the advantages of maximum surface area, least pressure drop, light weight and amazing structural strength. It can be made highly porous due to the nature of construction of the substrate used.

The fluted media, due its porosity, can act host to any desiccant, metal silicates and catalysts in its walls, depending upon its usage, like air drying, VOC removal, etc. Even for applications like NOx removal, excellent honeycombing is possible, to provide a high velocity air passage with a low substrate mass, high catalyst loading, and low heat carryover.

This innovation is a major advantage and sets it apart from the conventional honeycomb carriers. The DRI fluted media can easily be used up to very high temperatures and can take many desiccants and catalysts according to the end usage required.

Various permutation and combinations of substrates, chemicals, synthesizing processes and design features are possible, depending upon the application.

We have not only mastered the art of impersonating and recreating nature's wonder - honeycombs, but also the science of combining the substrates with chemicals, using various processes, that include: