By Varun Pahwa, President, Desiccant Rotors International | Publish Industry India | May 30, 2024

The manufacturing sector at present stands at a very interesting cusp of development. Bolstering at a phenomenal rate, the sector has come a long way over the years. Meeting the demand projected by the Indian market, the sector is on the way to instate its supremacy in the international market as well. To achieve this purpose, the country is making significant progress to become the manufacturing powerhouse across the globe.

But in order to create a strong foothold in the international market while also catering to the needs of the domestic market, it is essential to drive the productivity of the manufacturing units. Here, it is very important to understand the various complications of the industry to scale the production of the sector invariably. Elaborating on the same, the manufacturing units continuously reel under the influence of heat. The manufacturing facilities and shop floors are complex structures, housing heavy machinery for carrying out various critical processes. With a number of intricate processes being performed on a large scale, a lot of heat is disseminated by the facilities. Along a similar line, with temperature reaching its peak during the summer, further compounds the already existing problem.

The inability to deal with heat in a manufacturing setup can severely deteriorate the quality and account for substandard products. At the same time, the surging heat can give rise to uncomfortable working conditions for the occupants of the space. It has been observed that staying in excessive heat for a long period of time leads to the development of a phenomenon called heat stress. In addition to this, people can also experience swelling, cramps, and extreme exhaustion as a consequence of heat. Likewise, the hot and stuffy surroundings can meddle with the concentration and accuracy of the employees. All the factors together can risk the productivity of the manufacturing facilities. Along with this, the stagnant air within the premises creates a conducive environment for the proliferation of viruses and bacteria.

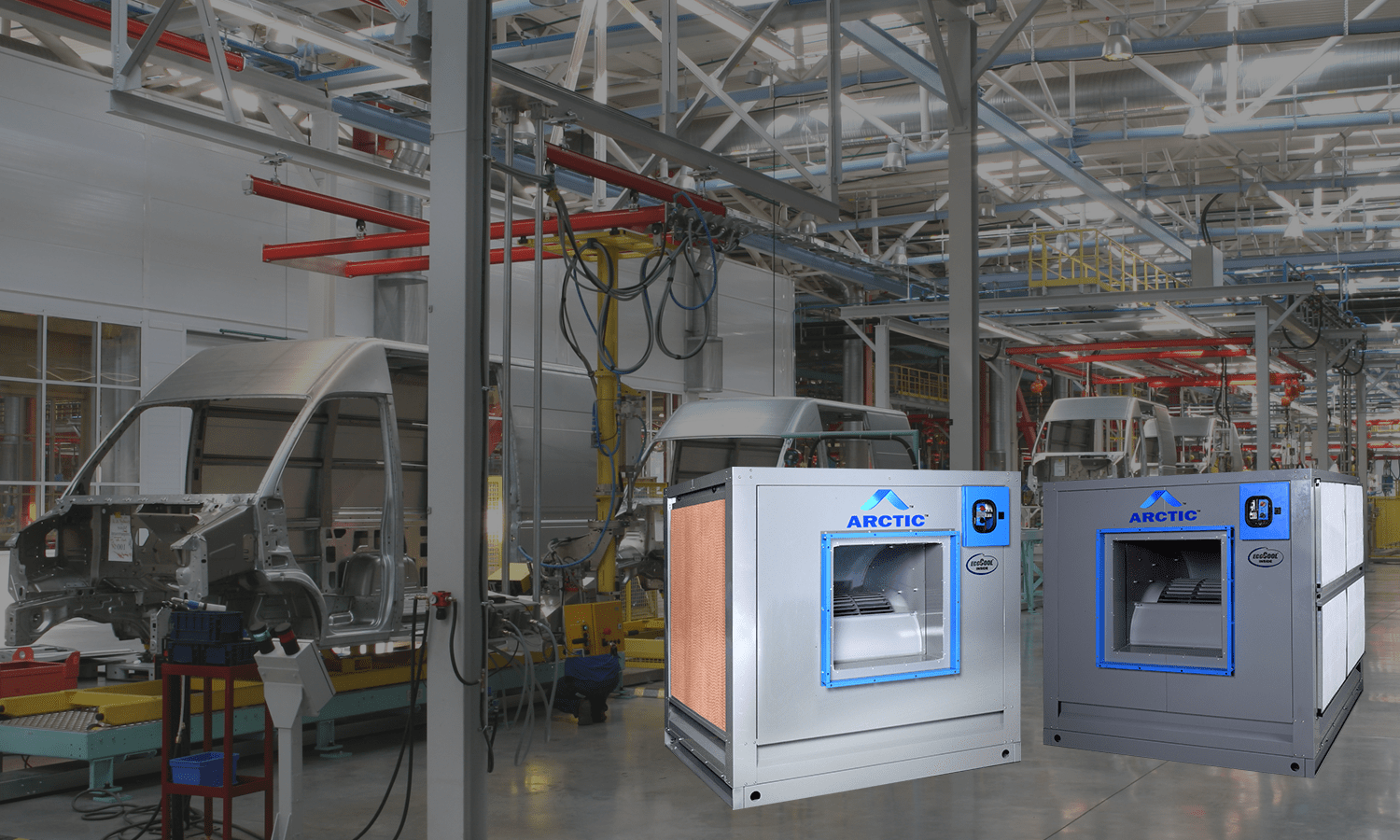

To address the problem, the industry leaders should focus on cooling down the space. But considering the large facility, it becomes tricky to cool the extra space. Moreover, with summer adding to the heat woes, industrial evaporative cooling comes to the rescue for cooling down the manufacturing units efficiently. Going for alternative cooling options, such as air conditioning, can be quite challenging and impractical at the same time. Considering the area of the facility, innumerable air conditioning systems are required to cool down the space, resulting into spike in installation, maintenance, and operational costs. But on the contrary, evaporative cooling comes with economical solution, requiring minimal capital and installation costs. Likewise, the average price to setup the system is just one-fourth the expense of installing an air conditioning system.

The proficiency of industrial evaporative cooling to offer cost-effective solution comes from its ability to utilize natural resources to cool down the space. Taking an environmentally friendly route, it draws 100 percent of the natural air from the ambient environment. In the process, it enables a continuous supply of oxygen, which, along with cooling down the premises, proactively eliminates fumes, odor, carbon dioxide, various airborne impurities, and the dust that is built within the enclosed facility. Owing to this, the mechanism goes a long way in ensuring the continual circulation of fresh air, which bodes well for mitigating the sultriness of space. Playing a crucial role in eliminating stagnant indoor air from the manufacturing unit, it gets rid of viruses and bacteria that thrive in hot, humid conditions. Cumulatively, industrial evaporative cooling serves the dual purpose of cooling down the space along with achieving quality indoor air at the same time.

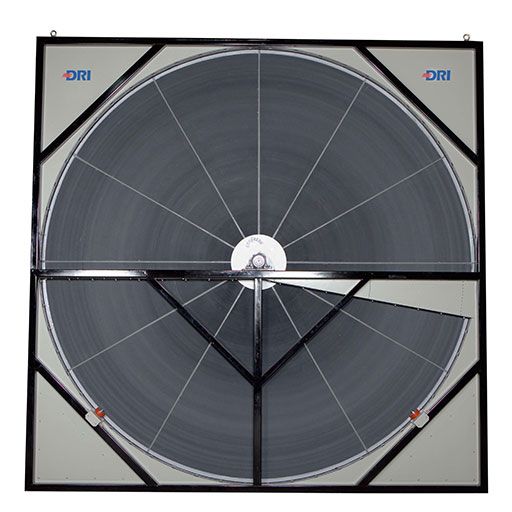

Elaborating on the benefits of the cooling mechanism, making use of natural resources, it significantly reduces the temperature by 10 °C to 12°C. It deploys water-saturated cooling pads to filter out hot, dry air by initiating water evaporation to form cool vapours for bringing about the cooling effect. Additionally, to further drive the efficiency of the system, the innovative coolers make use of high-adsorbent materials that enhance the performance of the systems. Reducing the overall consumption of energy significantly, the cooling mechanism utilizes 80 percent less electricity as compared to other alternatives available in the market. Along similar lines, opting for ARCTIC coolers bodes well for driving the maximum output, which comes with the ability to achieve the highest quality air while cooling down the space in the most hassle-free way.

Furthermore, the coolers are well equipped with advanced technologies to drive the efficacy of the systems. It employs indirect evaporative cooling exchangers which comes with the proficiency to evaporate the water. Consequently, it bodes well for cooling the air without adding any moisture to the indoor environment. Along with this, the coolers make use of highly-efficient and reliable EcoCool evaporative cooling pads that provides the ideal solution for bringing down the temperature of the space. The highly durable pads are well adept at converting the sensible heat to latent heat which ultimately results in supply of humidified and cold fresh air across the enclosed space.

Therefore, looking at the complexity of the manufacturing units, industrial evaporative cooling emerges as the most viable option to fuel the efficiency of the plant. It plays a crucial role in providing the occupants with cool, fresh air, enabling them to concentrate better at their work, and also aiding in minimizing the health risks due to hot and sultry conditions. At the same time, it also protects the integrity of the machines, which might get damaged due to overheating. As a result, by alleviating the various threats looming over the facility, the cooling mechanism comes with the proficiency to drive the productivity of the manufacturing units.