Addressing Humidity and Temperature Differences

Maintaining optimal humidity and temperature levels in a facility can be challenging. Simply adjusting the quality of fresh air entering the building can help, but it often comes at the cost of significant energy consumption. Energy Recovery Wheels (ERWs) play a vital role in HVAC systems. While many energy recovery devices focus solely on heat transfer, ERWs, a type of energy recovery ventilators (ERVs), passively transfer both sensible (heat) and latent (moisture) energy between incoming and outgoing airflow.

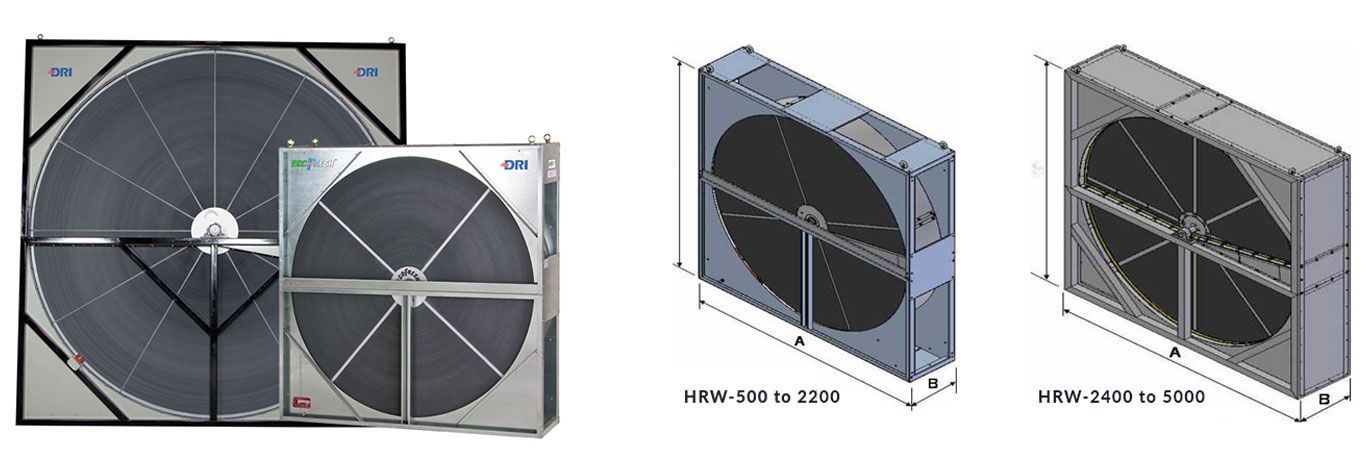

Understanding the Energy Recovery Wheel

The Energy Recovery Wheel consists of a rotating wheel with absorbing materials that offer a large internal surface area, facilitating efficient heat exchange (energy transfer). Additionally, the spinning wheel is coated with a desiccant material that absorbs moisture, aiding in the transfer of latent energy.

The Benefits of Energy Efficiency in Manufacturing

In manufacturing, energy consumption is a significant factor in production costs. As the industry becomes increasingly competitive, businesses strive to reduce expenses without compromising product quality. Energy-efficient technologies can be crucial in improving processes and overall quality, leading to increased output while reducing costs. Embracing energy efficiency results in cost savings and aligns with sustainability goals, reducing emissions and the company’s carbon footprint. Prioritizing energy efficiency allows plant managers to reduce energy consumption without compromising product quality, making it an excellent business strategy for manufacturing companies.

Energy Recovery Wheels for Enhanced Efficiency

Energy Recovery Wheels utilize porous materials that efficiently transfer both sensible (heat) and latent (moisture) energy, minimizing the wastage of conditioned indoor air. By incorporating desiccants such as Silica Gel or other molecular sieves, the cost of air conditioning can be reduced, resulting in potential savings of up to 50%.

Limitations and Considerations

It is essential to acknowledge that ERWs come with certain limitations. Concerns regarding cross-contamination arise when fresh air is introduced to areas that handle lethal products, oncology medications, or hormone-sensitive products. Proper assessment and design considerations are crucial to ensure the appropriate use of ERWs in such applications.

Understanding the Working Principle of ERWs

The transfer of energy occurs between the supply air and exhaust air in an ERW system, adhering to the principles of the first law of thermodynamics. The ERWs are positioned within building ventilation systems where exhaust and outside air flow in different directions but are adjacent. As the ERW rotates, one-half of the wheel is exposed to outdoor air, while the other half faces contaminated air. This configuration enables a counterflow exchange, allowing the ERW to absorb desired humidity and temperature from the outside air and passively create the desired temperature within the building through different driving mechanisms.

The rotating wheel facilitates energy exchange from the higher to lower airstream, utilizing sensible energy (via a honeycomb metal matrix) and latent energy (via a moisture-absorbing material such as silica gel). Outdoor and indoor airflows are aligned in parallel ducting. As the outdoor air passes through the ERW, the exposed half of the wheel absorbs sensible and latent energy, transferring it to the inside air. This process keeps the airflows separate, and the exchanged air entering the premises is either warmed or cooled based on the physical properties of the Energy Recovery Wheel.

By recycling the beneficial properties of air inside the building, rather than relying on new energy sources, the exhaust air preheats the supply air in winter and pre-cools it in summer. The desiccant coating plays a crucial role in achieving these desired outcomes. Some systems even use Energy Recovery Wheels to reheat supply air after it has been cooled, offering an effective means of humidity control.

Maximizing HVAC Efficiency with Energy Recovery Wheels

Incorporating Energy Recovery Wheels into HVAC systems can improve energy efficiency while maintaining indoor comfort. By utilizing the capabilities of ERWs, facilities can reduce energy consumption and operating costs and create a healthier indoor environment. When selecting an ERW system, you must consider specific requirements and consult experienced HVAC experts. Embrace the power of Energy Recovery Wheels and unlock the potential for enhanced HVAC efficiency in your facility.

What are Purge Sections?

ERW designs incorporate purge sections to mitigate the risk of cross-contamination. These sections leverage the pressure difference between outdoor and return air to purge the trapped contaminated exhaust air with clean air before it enters the supply airstream. Strategically positioning the purge section within the ERW acts as a safeguard, eliminating any potential for cross-contamination and ensuring that only clean, fresh air is supplied to the indoor environment.

With DRI Rotor’s expertise in energy-efficient designs and commitment to delivering sustainable solutions, you can rely on our team to optimize your ventilation system’s performance and create a healthier, more comfortable indoor environment. Request a call back now.