The Energy Recovery Wheel - EcoFresh Energy / Enthalpy Recovery Wheel, which recovers total energy (sensible and latent), assists in meeting all the requirements of improving Indoor Air Quality (IAQ), humidity control and energy saving.

DRI is proudly the world's largest manufacturer of desiccant coated aluminium substrate Energy Recovery Wheels and has an installation history of 25+ years. It also has the largest installed base of such wheels all over the world in the most iconic buildings.

DRI offers the Highest Recovery Enthalpy Wheels in the world (Aluminium substrate coated with a choice of desiccants). These are incorporated into a Fresh Air Handing Unit or Energy Recovery Ventilator. In some cases, the wheel may be installed standalone with ducts.

Incorporation of EcoFresh Heat Wheels into the air-conditioning system means more outdoor air at lower energy cost (reduced loads).

Energy Recovery Wheels may also be known in the industry as Energy Conservation Wheels, Heat Wheels, Enthalpy Wheels, or Sorption Wheels. Sensible-only recovery Wheels are also referred to as Condensation Wheels. Hygroscopic recovery wheels have latent efficiency much lower than sorption wheel

All DRI energy recovery wheels are certified. Eurovent certification and all AHRI program certification details are available on the website, in catalogs, and in writing to us.

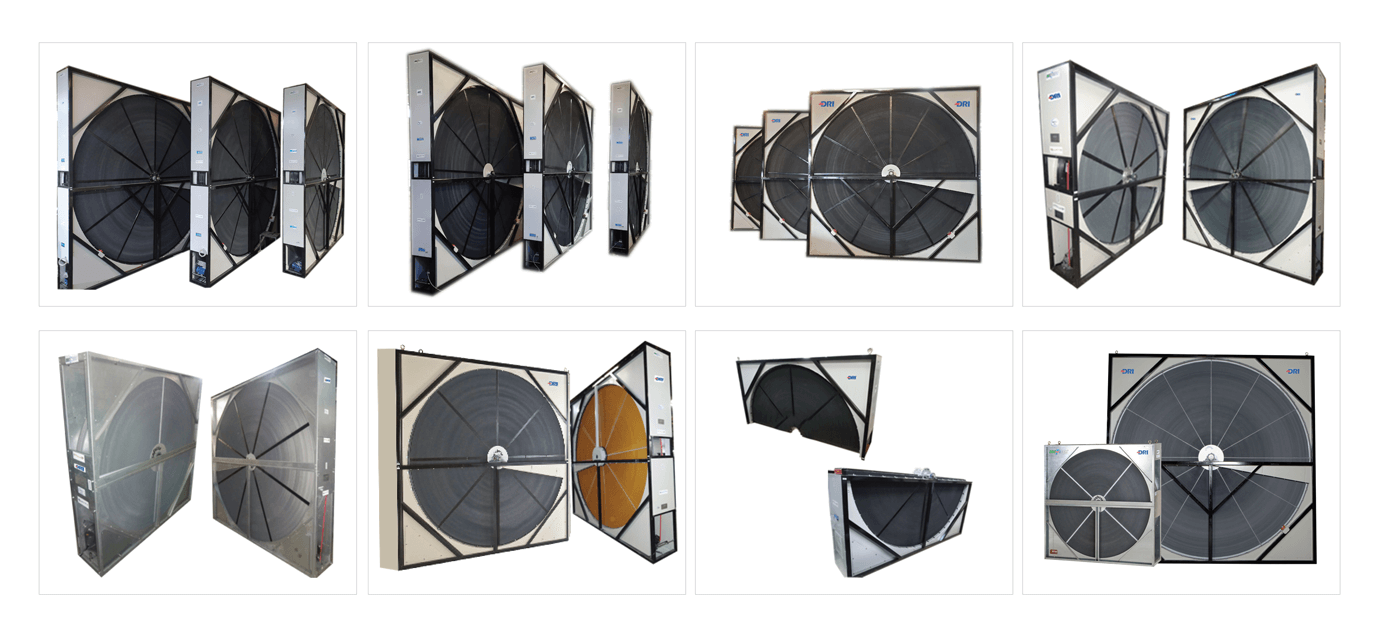

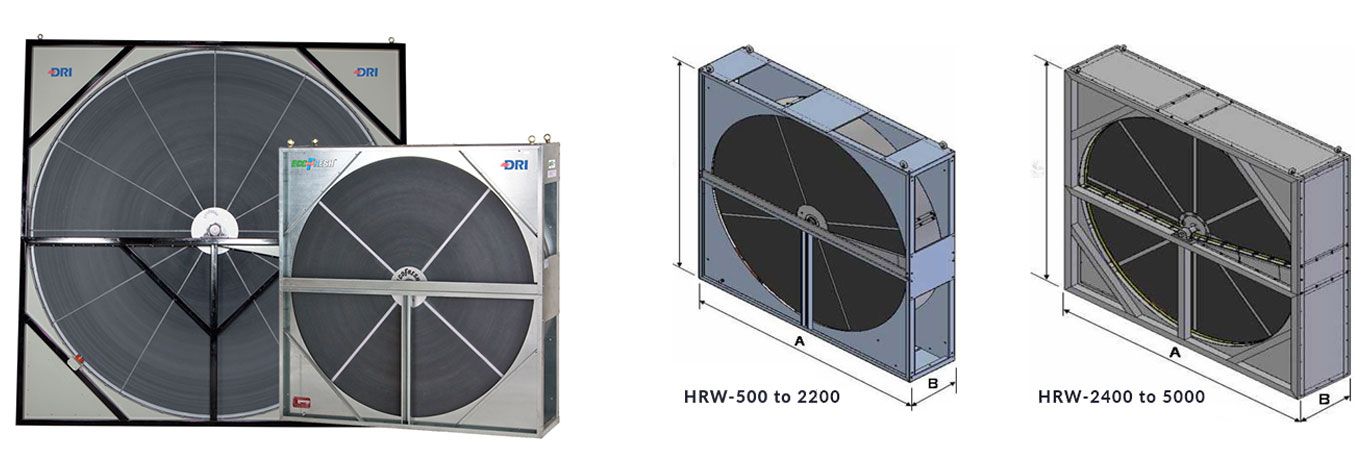

We offer various diameters and depths of the rotors incorporated into cassettes. Rotors and Cassettes up-to a certain diameter are monolithic as a standard.

Higher diameters on account of handling and shipping are in half-moon configuration as a standard. Customization of cassettes: dimensions, construction, segmentation, and material of cassette construction for specific project requirements is possible. Both vertical and horizontal cassettes are available. Replacement wheels of all types are also possible and available in easy retrofit options. Feel free to contact us.

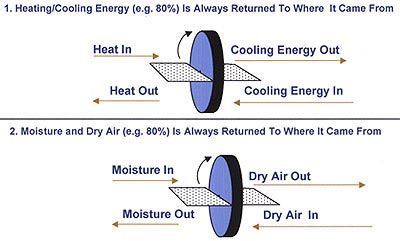

In a typical installation, the wheel is positioned in an Air Handling Unit so that it is divided into two half moon sections.

Stale exhaust air is drawn through one half and outdoor air through the other in a counter flow pattern. At the same time, the wheel is rotated. Sensible heat is transferred as the metallic substrate picks up and stores heat from the warmer air stream and gives it up to the cooler one.

The desiccant-coated metallic substrate adsorbs moisture from the air stream with a higher humidity ratio, transferring latent heat, and releasing the moisture through desorption into the air stream with a lower humidity ratio.

Higher Selectivity . . . Almost no cross contamination:

EcoFresh Energy Wheels use desiccant Molecular Sieve 3Ã… (EcoSorb 300) coated/used on an aluminium substrate. This limits the cross-contamination to an absolute minimum and ensures the exclusion of contaminants in the air streams while transferring water vapor molecules.

The Purge section provides strict separation of air flows, preventing the carryover of bacteria, dust, and pollutants from exhaust air to supply air. The purge section and labyrinth sealing system limit cross-contamination down 0.04% of the exhaust air concentration by volume. This can be further reduced through more strategies.

A vertical run out of less than 1 mm per 1000 mm results in extremely low leakage across the seals.

Wheel rotation speed control helps to limit frost formation by keeping the exhaust air temperature above the dew point.