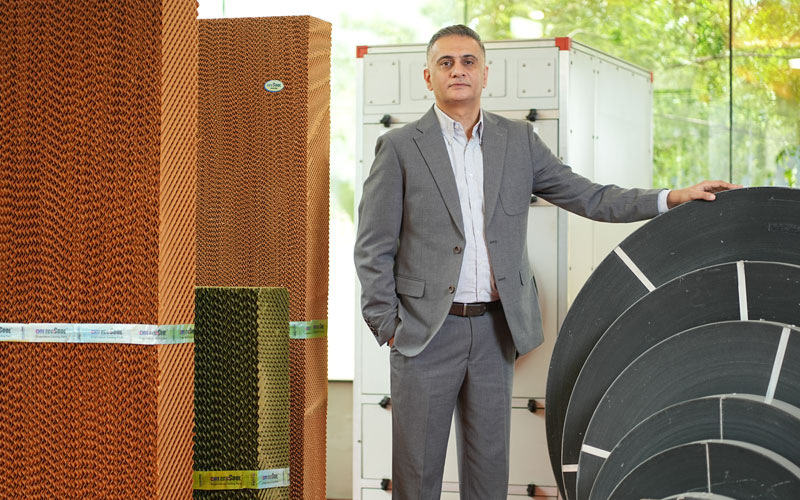

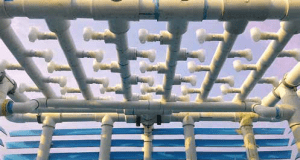

Treated Fresh Air Handling Units (TFA)

DRI’s Treated Fresh Air Handling Units (TFA) are the most sought-after product for improving IAQ within large enclosed buildings. It comes with the proficiency to thoroughly ventilate the space while driving energy efficiency in the facility at the same time.

EcoFresh Molecular Sieve Coated Heat Wheel is integrated into TFA units for facilitating the achievement of good IAQ and energy saving in a single unit. There is a flexibility of adding modules as well for enabling cooling, heating, humidification, high-efficiency filtration, mixing, sound attenuation, etc.

The system allows easy maintenance and resides well for free, reliable operation. Similarly, even the filter & fan assembly requires minimal maintenance. Elaborating on the salient features, TFA incorporates standard filters – exhibits innovative design for connection system and offers a wide range of options, making it the ideal choice for hospitals, hotels, malls, offices, airports, educational institutes, pharma facilities, cold storages, and all air-conditioned spaces.

The pioneering system is capable of driving various functions in the same casing. It offers the widest range of air quantities, TFA deploys the best technology for casing manufacturing, and are AHRI certified.

The machine is highly advanced to demonstrate impressively low pressure drops across all components coils, heat exchangers, etc. to provide the lowest possible pressure drop in proportion to the highest possible efficiency, resulting in very low LCC.

Altogether, the TFA system is ideal for fresh air solutions in a conditioned space that not just enhances the IAQ but promotes energy saving as well. As a result, it is adept at meeting ventilation standards effectively while abstaining from increasing the energy cost in the process. The ability to precondition the incoming fresh air all year round significantly contributes to reducing the system capacity by 30 to 65%. Consequently, the systems go a long way in maintaining optimal humidity levels without incurring additional cost.

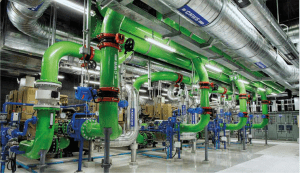

Dedicated Outdoor Air Systems (DOAS)

DOAS ULTIMA is one of the pioneering developments of DRI that allows designers to provide ultimate fresh air ventilation as a single source responsibly. It is a unitized Fresh Air Management System that enables handling of moisture load by utilizing Ventilation Air.

DOAS consists of highest recovery Enthalpy Wheels, EcoFresh, and patented Passive Desiccant Wheels, which promote the achievement of lower dew points, and that too without requiring a DX system. The Patented Desiccant Wheels support a unique configuration that conducts regeneration without requiring any active energy.

The system is proficient at providing fresh air at low Dew Points using chilled water coils. DOAS works on the mechanism of handling fresh air load and the room’s internal latent load by decoupling them from the internal sensible load. Here, the sensible load is majorly managed by a parallel – terminal unit/system. At the same time, the system removes moisture from a saturated air stream without heat/thermal regeneration.

DOAS is specifically designed to meet the international standards and goes a long way in driving energy savings of upto 55%. The advanced technology is highly preferred in offices, hospitality sector, hotels, malls, hospitals, etc. for its ability to improve the IEQ.