Prioritizing good air quality in workspaces has been gaining a lot of traction in recent years. With employees spending the majority of their time in their offices, it becomes crucial for organizations to provide a healthy and safe environment to them. The modern workspace infrastructure is generally characterized by enclosed spaces, lacking windows to accommodate air conditioning systems. As a result, the structures give rise to a sealed indoor environment with hardly any scope for fresh air ventilation.

Unlike the common misconception that air conditioning improves the air quality of the space, it comes as a surprise for many that systems recirculate stale air. Additionally, with the space occupied by a large number of people, it continuously contributes to the build-up of carbon dioxide and pollutants within the space as it is unable to find an escape to the outside. All the factors together account for poor air quality and severely impact the health of the occupants. If left unattended, the poor IAQ can give rise to a range of health issues in a person, such as respiratory issues, allergies, and serious conditions of cardiovascular disease as well.

Moreover, continual exposure to poor IAQ can result in the development of Sick Building Syndrome, where the occupants are very likely to face breathing issues, headaches, asthma, fatigue, and pain in the eyes. Severely compromising the health and comfort of the person, lethargy and absenteeism are some common issues that impact the productivity of the individuals. As a result, it becomes a prerequisite to install technologies that improve the air quality of the workspace, aimed at enabling an efficient work process accompanied by enhanced concentration.

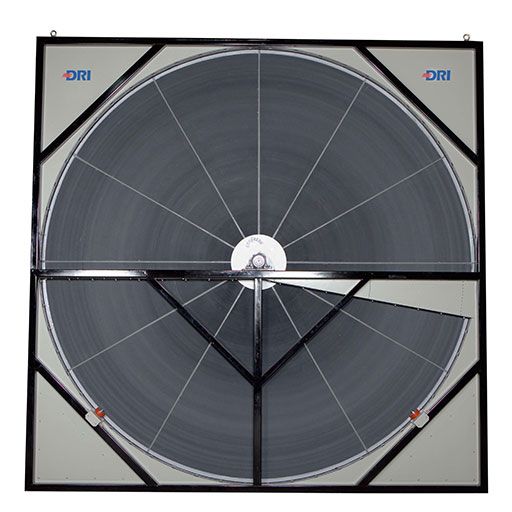

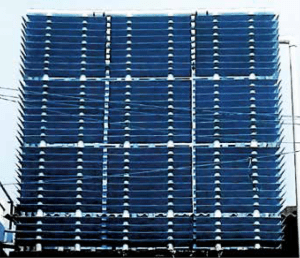

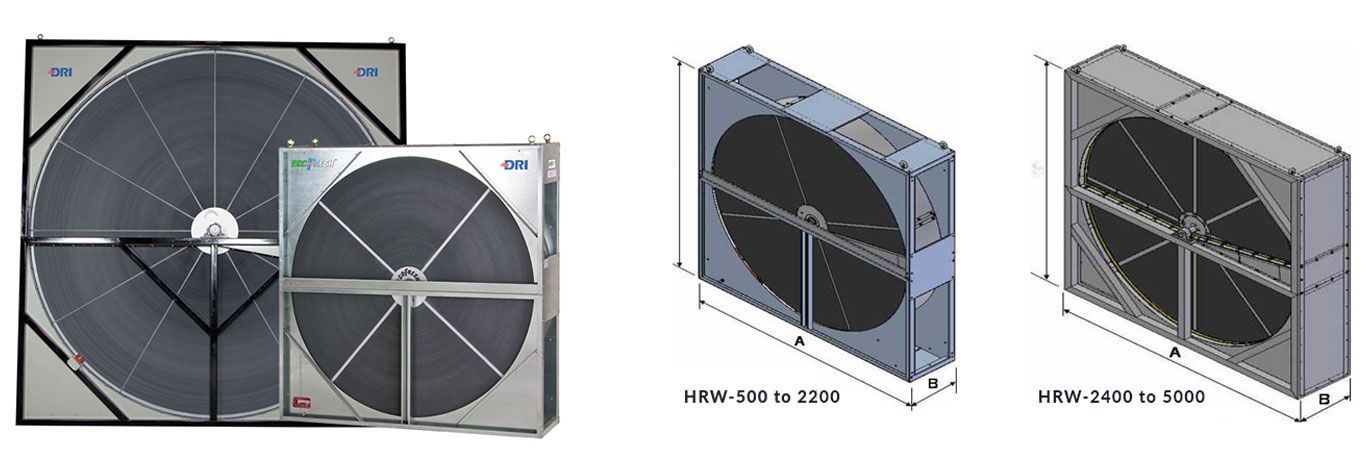

To achieve good air quality, employing Treated Fresh Air Handling (TFA) systems is essential. These systems precondition the incoming fresh air to meet ventilation standards and maintain excellent indoor air quality (IAQ). By filtering and treating the air before it enters the space, TFA systems eliminate pollutants, allergens, and contaminants, effectively impeding the spread of airborne diseases. As a result, these units ensure a consistent supply of clean and healthy air, significantly reducing health issues associated with poor air quality. Additionally, TFA systems are equipped with energy recovery wheels, which recover both sensible and latent energy, contributing to improved IAQ, humidity control, and energy savings.

The advanced systems bode well for achieving optimal indoor air quality throughout the year, irrespective of the weather conditions outside. Providing a stable and comfortable environment, the systems invariably contribute to high levels of engagement and motivation among the employees, enhancing their overall performance round the year.

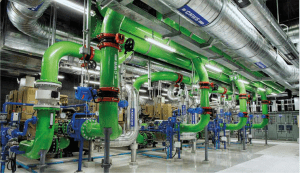

In the pursuit of meeting the ventilation standards, the advanced technologies also vouch for energy efficiency. Striving to save energy while maximizing the energy recovery efficiency, they eliminate the need to increase the energy costs of the building. Here, by exercising the efficient airflow for ensuring the appropriate circulation of fresh air, the units come in handy for reducing the need for excessive heating and cooling of the space. Taking a holistic approach, they not just contribute to saving energy but extend to reducing the operational costs of the workspace at the same time.

To achieve the purpose, the Treated Fresh Air Handling Units ensure uniform distribution of air, which significantly curtails the demand for heating, ventilation, and air conditioning (HVAC) systems. Reducing the overall load of the system, there is a remarkable plunge in the operational cost as well as the energy consumption of the building. Consequently, by installing the systems, businesses can successfully achieve the twofold task of enhancing air quality within the workspace, which clocks substantial energy savings. While focusing on optimizing the air quality of the space, humidity is often neglected by people. But exercising humidity control is a crucial step towards providing a healthy indoor environment to the employees.

Here, the Dedicated Outdoor Air Systems (DOAS) harness the benefit of unique passive dehumidification wheels for ensuring adequate ventilation of the space. Coming with the ability to eliminate indoor air pollutants while monitoring humidity levels, the system replenishes fresh air to create a more pleasant and productive workspace.

The ability to control the relative humidity plays a crucial role in resisting the growth of mold, bacteria, fungi and prevents the issue of unpleasant odour and discomfort caused by excess moisture. In addition to this, monitoring the humidity can go a long way in safeguarding the office equipment and materials from any potential damage, retaining their longevity and reliability for a long time. Looking at the wide gamut of advantages optimal air quality has to offer for the workspace, it goes a long way in scaling the overall performance of the business.

Promoting the health and safety of the employees along with a comfortable space invariably improves the concentration and productivity of the occupants. In the process, employing Treated Air Handling Units can be considered a strategic business investment because it offers a comprehensive solution for providing energy-efficient ventilation. Conducting pre-conditioning of incoming air guarantees a consistent supply of fresh air. At the same time, monitoring the humidity levels of the space, the systems are an ideal option for ensuring the health and safety of the occupants.

Authored by:

Varun Pahwa

President,

Desiccant Rotors International