By D Roy Choudhury, AVP, Desiccant Rotors International | The Machinist | May 21, 2024

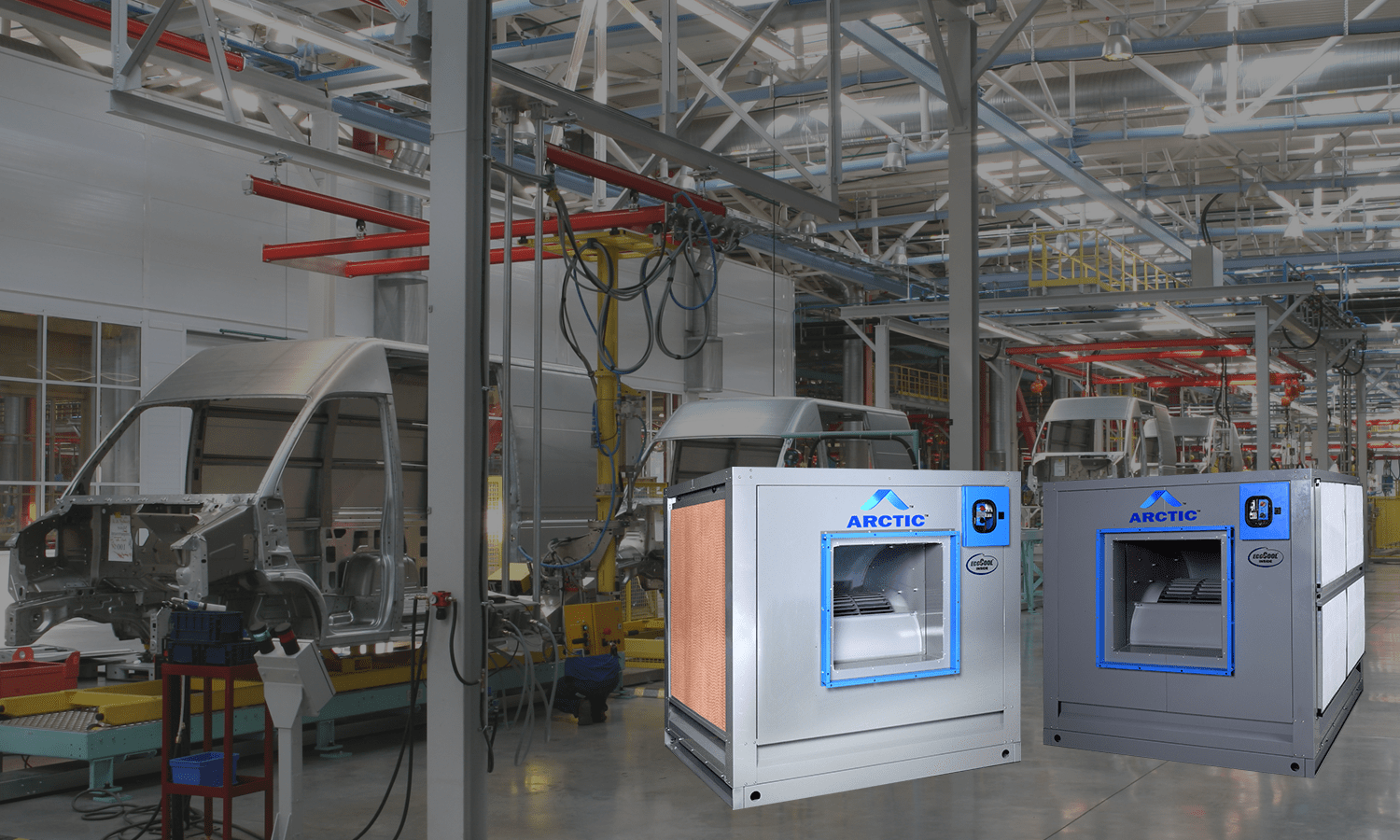

Industry players are seeking cost-effective solutions for cooling their spaces in anticipation of the hot summer months. The article outlines why evaporative cooling is a viable option for effectively cooling large spaces, such as manufacturing facilities.

With the onset of summer, heatwaves remain a matter of concern among people. Adding to it, working in industrial plants compounds the heat problem as the spaces are inherently complex structures containing heavy machinery where critical processes are carried out. Considering the critical nature of these processes, they further contribute to the dissemination of a significant amount of heat. Predictions based on IMD reports indicate an impending heatwave expected to reach its peak between May and June, can further worsen the situation in an industrial plant setup. The heat within the facility can lead to deterioration of the products, which can immensely compromise the quality and jeopardise the profitability of the company. In addition to this, inadequate cooling owing to the complexity of the structure coupled with the rising temperatures can account for uncomfortable conditions, making the premises unsuitable for working. Additionally, prolonged exposure to excessive heat can lead to a phenomenon called heat stress among the occupants. Symptoms such as swelling, cramps, and exhaustion can also develop among the employees.

These factors collectively impede the productivity of the employees and interfere with the smooth functioning of the day-to-day operations. Therefore, to optimise the output of the plant, it is imperative to maintain the temperature within comfortable limits to boost the performance of the employees. However, cooling down the excess space in large facilities consumes a significant amount of energy. Moreover, with the impending sweltering summer,

industry players are seeking cost-effective solutions to efficiently cool their spaces. Industrial evaporative cooling emerges as the most viable solution for effectively cooling large spaces. Installing air conditioning can be challenging and costly, requiring a large number of systems and leading to high installation, maintenance, and operational costs. Conversely, evaporative cooling ventilates premises in the most economical way, with minimal capital costs for installation and setup prices just one-fourth of those for air conditioning systems. Industrial evaporative cooling provides a cost-effective solution by continuously utilising natural resources to cool spaces in an environmentally friendly manner. By extracting 100 per cent natural air from the surroundings, this mechanism ensures a continuous supply of oxygen to cool large industrial spaces while also eliminating fumes, odours, carbon dioxide, airborne impurities, and built-in dust. This circulation of fresh air reduces sultriness and removes stagnant indoor air, which is responsible for the proliferation of viruses and bacteria. Therefore, in addition to fulfilling the task of cooling down the plant, evaporative cooling plays a crucial role in enhancing the indoor air quality as well. Evaporative cooling significantly lowers temperatures by 10°C to 12°C by employing water-saturated cooling pads to filter out hot, dry air. This mechanism initiates water evaporation to form cool vapours, thereby providing a cooling effect. High-adsorbent materials are utilised to further enhance saturation efficacy, ultimately reducing the overall running costs of the machines. Consequently, there is a notable reduction in energy consumption, with evaporative cooling systems using 80 per cent less electricity compared to other cooling solutions on the market. Brands such as ARCTIC can proficiently achieve the required air quality and effectively cool spaces in a comfortable and hassle-free manner. Considering the wide array of advantages evaporative cooling offers, it has the potential to increase plant productivity. By improving employee comfort and concentration in hot conditions and ensuring optimal machine performance by preventing overheating, these cooling systems contribute to both employee well-being, safety, and operational efficiency within the plant.