Rahul Aeron, AVP-Sales, DRI | Cooling India | March 22, 2021

Rahul Aeron, Assistant Vice President, DRI talks about products, new air cleaning mechanisms technologies while sharing responses with Gopal Anand from Cooling India and predicts that he is seeing an increase in demand from the healthcare sector in new normal times.

What is your perception about indoor Air Quality market and post pandemic, what changes do you foresee in IAQ market?

The IAQ market has been growing steadily over the last few years. Some of the major factors fuelling the growth are ‘Green Buildings’ incorporating sustainable design, increasing levels of outdoor pollution, growing awareness of health/productivity benefits of good indoor air quality etc. This has resulted in lot of air cleaning equipment being used for maintaining indoor air quality while compromising on ventilation rates.

The pandemic has reinforced the focus on ventilation and the age-old saying “Dilution is the solution for indoor pollution” has again found its relevance. Post pandemic, we foresee the ventilation rates would be increased and wherever possible, 100% outdoor air systems will be designed/ used. Also, as health and safety takes a front seat, HVAC systems in buildings need to be able to deal with not just pollutants but also the ability to maintain the right humidity. In order to avoid growth of viruses and allergens, such as mold and mildew, which may release spores that directly affect humans, buildings are integrating advanced HVAC systems. Air cleaning mechanisms will also see a lot of new technologies and usage of technologies, like Ultraviolet rays (UV), Photo Catalytic Oxidation (PCO), Needle Point Bipolarization etc.

What is the product line-up of Desiccant Rotors International Pvt. Ltd. (DRI) as well as products especially suited to Indian market?

DRI specializes in providing innovative air solutions for conditioned and unconditioned indoor spaces. DRI’s “Green” products help optimize energy performance of the air conditioning systems. These products result in a considerable reduction of installed tonnage, reduction in utility bills for the product’s entire life cycle, enhanced IAQ and productivity, and reduced health risks. DRI products also help procure rating points for energy certification programs like Green star and LEED.

DRI’s centralized coolers also provide comfort on the shop floor level at an economical rate by enhancing ventilation and cooling the air.

Some of our products are:

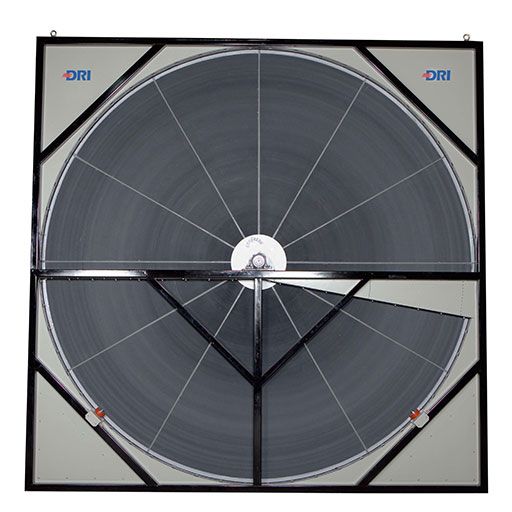

- Dedicated Outdoor Air Systems and Treated Fresh Air Unit (TFA) incorporating Energy Recovery Wheels

- Energy Recovery Ventilators (ERVs)

- Evaporative Cooling Pads (ECPs)

- Ducted Centralized Evaporative Coolers

- Indirect-Direct Evaporative Coolers

Has the market share of DRI products been impacted in the last 9 months of literal inactivity? Now, what prospects do you see for market share of DRI products in respective segments?

We were able to work through most of the initial lockdown last year, as our industry and many of our activities come under essentials. This, coupled with the pandemic induced growing focus on air quality and ventilation with regards to health, has not really caused any fluctuation in our market share. We are seeing an increase in demand from the healthcare sector, which of late, has become even more important. As usual, we always have continued to be a company whose products are: Made in India with sense of pride for India and the world.

Has the market share of DRI products been impacted in the last 9 months of literal inactivity? Now, what prospects do you see for market share of DRI products in respective segments?

We were able to work through most of the initial lockdown last year, as our industry and many of our activities come under essentials. This, coupled with the pandemic induced growing focus on air quality and ventilation with regards to health, has not really caused any fluctuation in our market share. We are seeing an increase in demand from the healthcare sector, which of late, has become even more important. As usual, we always have continued to be a company whose products are: Made in India with sense of pride for India and the world.

Please brief us about current activities of Pahwa group flagship companies DRI and Bry-Air, that showcased air treatment solutions at Acrex 2020. As you may know, now there is strong emphasis on fresh air due to coronavirus. What is your say?

Pahwa Group comprises four companies that are the pillars: Bry-Air, DRI, Delair and Technical Drying Services (TDS). These companies are focused on industrial air treatment solutions and commercial building air conditioning products. Our products are manufactured in India for the world.

DRI products mainly focus on the commercial segments, for instance, healthcare, hospitality, commercial buildings, any large conditioned space and factories. DRI provides indoor air quality solutions for commercial buildings like hotels, hospitals, malls, airports, offices. Economical shop floor cooling systems are also part of our portfolio.

DRI has been at the fore front for supply of Treated Fresh Air Units (TFAs) incorporating Energy Recovery Wheels. Also DRI’s ‘Dedicated Outdoor Air Systems (DOAS)’ helps ventilate the buildings as well as maintain relative humidity inside the buildings. The latest addition to the family of DOAS is a range with refrigeration systems on board which not only saves energy but also uses waste-heat to remove the moisture from air.

Bry-Air and Delair equipment are mainly used by all industries viz., pharmaceutical, F&B, defence, electronics, packaging, cold storage and other industries.

Could you highlight about DRI’s portfolio of fresh air treatment systems and Evaporative cooling products?

‘Treated Fresh Air Units (TFA)’ also sometimes referred to in the industry as Fresh Air Handing Units (FAHU), are energy-efficient and offer significant savings. TFA are designed to treat the outside air using filters, and condition it to some degree using a cooling system, for providing fresh air to the environment. Our FlexAir TFA’s aim to create a ventilation system with low running costs and its advantage of energy recovery in turn cuts down air conditioning costs. These units include the Ecofresh Molecular Sieve coated Heat Wheel inside, which provides a complete solution for IAQ and energy saving in a single unit, with the option to add modules for cooling, heating, humidification, high efficiency filtration, mixing, sound attenuation, etc. The wheel slowly rotates between its two sections, conditioned air is passed through the wheel allowing the stale air that gets exhausted. During this process, the wheel absorbs sensible and latent energy from the conditioned air, which is used to condition (cool/heat) the incoming fresh air in the other section, during the second half of its rotation cycle. Thus, you can have more fresh air at lower humidity levels and energy costs inside your conditioned space. These TFAs are suitable for all climates including cold/dry, as well as hot and humid. They can be used in a number of spaces across industries such as hotels, bars, restaurants, hospitals, nursing home, operation theatres, supermarkets, department stores, office buildings, conference facilities, schools, auditoriums and so on.

In reference to ‘Evaporative Cooling Products’ evaporative cooling utilizes the basics of air and water to produce a very significant temperature drop. One of the main advantages of an evaporative cooling system is that it provides fresh, clean air. An evaporative unit circulates outside air and filters out all harmful dust particles and allergens. Hot fresh air is taken into the unit through wet EcoCool Cooling Pads. This cool humidified air is discharged indoors. DRI Arctic range of evaporative cooling units can also be specifically designed for the cooling of industrial and commercial buildings. These are capable of lowering the fresh air temperature by 7-12 degrees, for example the air-off temperature from the evaporative cooler for an outside temperature of 40-430C degrees can be lowered to as much as 28-300C degrees. This allows cool fresh air to circulate throughout a building forcing the stale hot air to be displaced. Unlike air-conditioning which operates with re-circulated air, Arctic coolers operate on the principle of air change and work as part of balanced ventilation system. This can be a highly efficient system, consistent in performance over a very long life.

Could you elaborate upon energy recovery systems and demand drivers for your products, while apprising about export activities too?

DRI Energy Recovery systems are focused on Enthalpy Wheels based systems. Our FlexAir range of ERVs and TFAs incorporate Enthalpy Wheels for Energy Recovery. Need of improved indoor air quality; need for productivity increase in workspaces; are some of the demand drivers. DRI’s 50% revenues are from exports, and we are now regularly exporting to almost 80 countries including US, China, UAE, Korea etc. We have exported systems as well as Energy Recovery Wheels, Desiccant Wheels and cooling systems to some of the most prestigious projects in the world.

The manufacturing activity came to standstill during the pandemic period. Summing up that, could you detail about the facilities and R&D activities as well as DRI’s participation in Eurovent Certification Program and Rotary Heat Exchangers?

Our manufacturing facilities are running full stream. We have just commissioned our new factory, which is a Platinum certified Green Factory Building. It is spread over 1,61,120 sqft., of built space.

We aim to be best in the world, especially in terms of product quality, performance, and innovation; so we invest a lot in R&D. We have six state-of-the-art test labs in Gurugram, and we are really investing a lot in innovative materials, concepts and testing laboratories, to test and verify product innovation.

DRI has been participating in both the certification programs for Rotary Heat Exchangers – AHRI & Eurovent.

DRI is an active member of the Green Building movement contributing to its activities spreading the concept. Could you detail us about the same? What has been DRI contribution towards this movement?

We are constantly conducting research and development activities to enable our products to be innovative, cost effective and most importantly sustainable. As the Green Building movement gains momentum, especially in India, we are likely to see even the standards and regulations provided by the authorities; adopting more and more sustainable methods and practices. We are regular participants in panel discussions, knowledge exchange sessions and informational sessions to help raise awareness about the concept of Green Buildings, for example ISHRAE holds regular round table sessions on various aspects of HVAC including sustainability, and quite often we are participants in the same.

What recovery momentum do you see for HVAC industry and what do you vision during new normal period?

The industry is picking up and is in revival mode, as we return to a new normal with appropriate health and safety guidelines in place. While the recovery may not be full until the vaccine rollout has much higher coverage. India is a country that will undoubtedly show a quick turnaround.