INDOOR AIR QUALITY & HVAC SYSTEM

Heating, ventilation, and air conditioning or HVAC systems are seeing new age developments as they integrate seamlessly within various spaces.

In recent years, people have become highly conscious about the health repercussions arising from poor indoor air quality. Consequently, to address the issue, there is a growing emphasis on indoor air quality (IAQ) with a focus on achieving the comfort of the occupants. This has invariably contributed to the rising demand for HVAC solutions that accomplish the dual purpose of regulating temperature along with removing pollutants and allergens from indoor spaces.

GREEN VISTAS

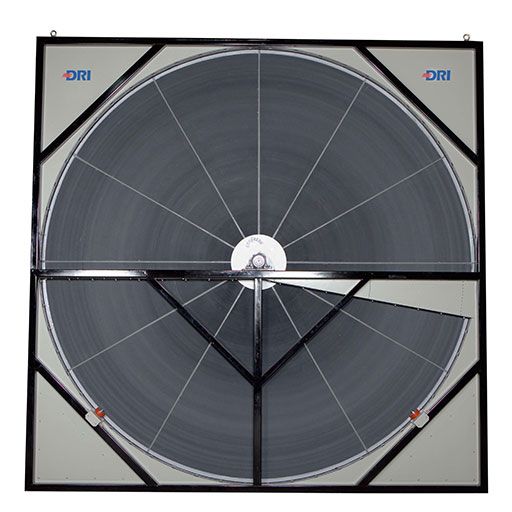

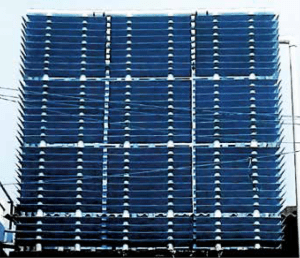

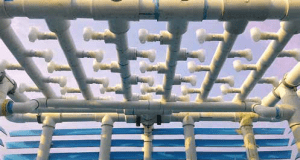

The HVAC industry is at a very interesting cusp of development. Driven by the growing importance of net-zero solutions in the segment, the industry is adopting energy-efficient solutions with alacrity to reduce the carbon footprint significantly. “To achieve this goal, the HVAC space is embracing Variable Refrigerant Flow (VRF) systems to ensure precise temperature control and zoning capabilities aimed at curtailing energy consumption with efficient operation as compared to traditional HVAC systems. To further strengthen the prospects of providing energy efficient solutions, the industry is focusing on reducing the cooling or heating load by resorting to natural methods of ventilation. By ensuring ingress of fresh air, ventilation plays a pivotal role in removing the contaminants from the space while maintaining comfortable temperature and humidity levels for the occupants. Here, by minimizing the dependence on heating and cooling systems, it contributes to reducing the consumption of electricity,” says Varun Pahwa President, Desiccant Rotors International.

Working towards improving the indoor air quality and hygiene of the space, HVAC systems are continuously innovating to curtail the proliferation of microorganisms in a closed space.

“The advanced technologies are also contributing to the enhanced automation of the systems for precise control of temperature, humidity, and other factors of the environment. Apart from this, the HVAC industry is progressing at a phenomenal rate by harnessing the benefits of collated data to practice predictive maintenance of the systems to troubleshoot and calibrate the systems to eliminate faults effectively that too in advance,” adds Pahwa.

Driven by the growing importance of net-zero HVAC industry has actively transitioned away

solutions in the segment, the industry is from refrigerants that cause Ozone depletion and adopting energy-efficient solutions with alacrity adopted refrigerants with low Global

to reduce the carbon footprint significantly. Warming Potential.

INDOOR AIR QUALITY

Working towards improving the indoor air quality and hygiene of the space, HVAC systems are continuously innovating to curtail the proliferation of microorganisms in a closed space. As a result, the industry is scaling its offering with the incorporation of advanced filtration systems to capture a wide gamut of airborne contaminants entailing bacteria, viruses, and allergens. “Additionally, the industry is further fortifying the antibacterial and antifungal measures with the integration of UV-light technology into the systems aimed at sterilizing air and surfaces for neutralizing harmful microorganisms. Along with this, the systems are proficient at inhibiting the growth of bacteria and fungi with antimicrobial coatings on the components contributing to the elevation of indoor air quality of the space. Going a step ahead, the industry is equipping the coolers with highly efficient and reliable antibacterial cooling pads that inhibit the formation of bacteria on the surface to provide the necessary protection against the diseases arising from microorganisms,” says Pahwa.

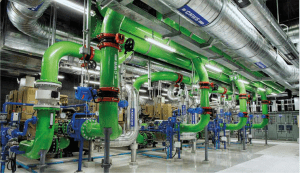

Smart controls, using Variable Frequency HVAC industry has actively transitioned away

Drives (VFD), now have a crucial role in from refrigerants that cause Ozone depletion

optimizing the performance of motors, and adopted refrigerants with low Global

including AC fan motors and compressors, Warming Potential.

in the HVAC industry